UV oil is a non film-forming substance, just like edible oil that does not form a dry film on the surface when placed in the air. UV oil immediately solidifies when exposed to ultraviolet light, such as sunlight, welding arc light, and plate lighting. Generally, lighting sources such as fluorescent lamps, incandescent lamps, and sodium lamps do not cause solidification. UV oil contains photoinitiators and diluents, which have a certain stimulating effect on human skin.

Considering the above characteristics of UV oil, the following points should be noted when using:

① The normal operating temperature of UV oil is between 50 ℃ and 55 ℃. During use, use a constant temperature water bath to circulate and heat the oil, so that the viscosity meets the design requirements, which is conducive to leveling and rapid curing.

② UV oil solidifies quickly and has strong adhesion when passing through the UV lamp irradiation area at a temperature of 50 ℃~60 ℃. But it's not that the lower the temperature under UV lights, the better.

③ Place the polishing machine in a location where direct sunlight is not allowed, otherwise UV varnish will solidify on the coating roller. If direct sunlight cannot be avoided, red and black curtains should be used to block the light.

④ When polishing, UV oil will scatter the ink on the polishing material into UV oil, making the polishing oil colored. After filtering and settling, it can still be used without the need for waste.

⑤ When polishing, UV oil should be immediately washed off with soap and water when it comes into contact with the skin, otherwise skin redness, swelling, and blistering may occur.

⑥ The viscosity of UV oil varies with the type of polishing machine, and special polishing oil should be selected according to the model. If the viscosity required by the polishing machine cannot be achieved, diluent can be used to reduce the viscosity or thickener can be used to increase the viscosity. This method will result in loss of UV curing speed, brightness, adhesion, etc.

⑦ UV oil flows into the rotating part of the transmission shaft and will stick to the shaft at high temperatures, affecting the transmission. Therefore, pay attention to cleaning the shaft head.

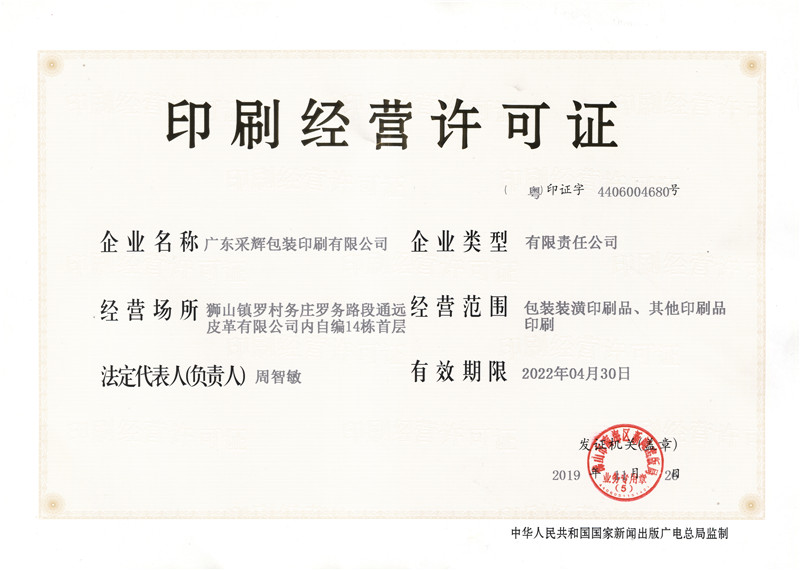

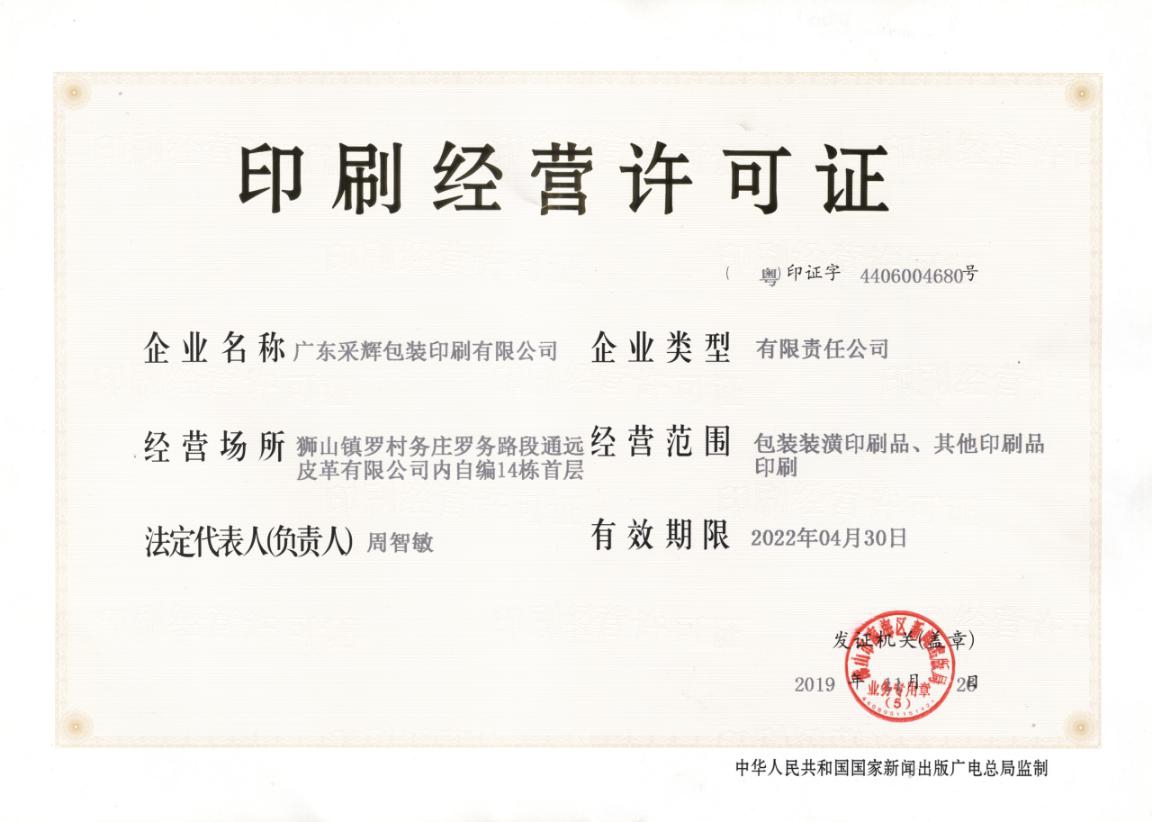

According to the surface properties of the substrate, special oils such as gold card paper oil and PET special oil are selected. Guangzhou Printing Factory chooses Caihui, please feel free to call us at any time!